Adhesive Backed Laser Sheet: From process characteristics to daily applications

2025-07-31

As a new material that is attracting much attention at present, Adhesive Backed Laser Sheet has become a highlight with the unique texture of laser carving and convenient installation of the backing glue design. Decorative expressiveness and scene adaptability are its core keywords. While meeting the needs of visual aesthetics, It also provides flexible solutions for material processing in daily production and life.

Process principle and visual advantages of laser texture

The visual charm of the backing glue laser comes from the fine laser processing technology. Through a laser of a specific wavelength, precise etching is carried out on the surface of the material to form a micron-level concave and convex texture. These textures show regular changes in the refraction and reflection of light, resulting in metallic texture, gradient luster and even holographic effects. Unlike traditional printing or film, laser texture is the physical change of the surface of the material. It will not wear or fade the pattern with the passage of time, and can maintain a vivid visual impact for a long time, which makes it more advantageous in scenes that require the durability of decorative effects.

Installation logic and practical considerations for backing adhesive design

Back glue design is the key to its popularity in practical applications. The self-contained pressure-sensitive adhesive layer has undergone many adhesive tests to ensure that it can fit closely with a variety of common materials such as wood, plastic and glass, and the pasting process does not require professional tools, and ordinary people can operate it. More importantly, the rubber layer of high-quality backing glue laser chips has good weather resistance, and it is not easy to open the glue in temperature changes or humid environments. For example, when used for bathroom mirror decoration or outdoor equipment marking, it can stably maintain the pasting state and reduce post-maintenance costs.

Matching logic of material characteristics and usage scenarios

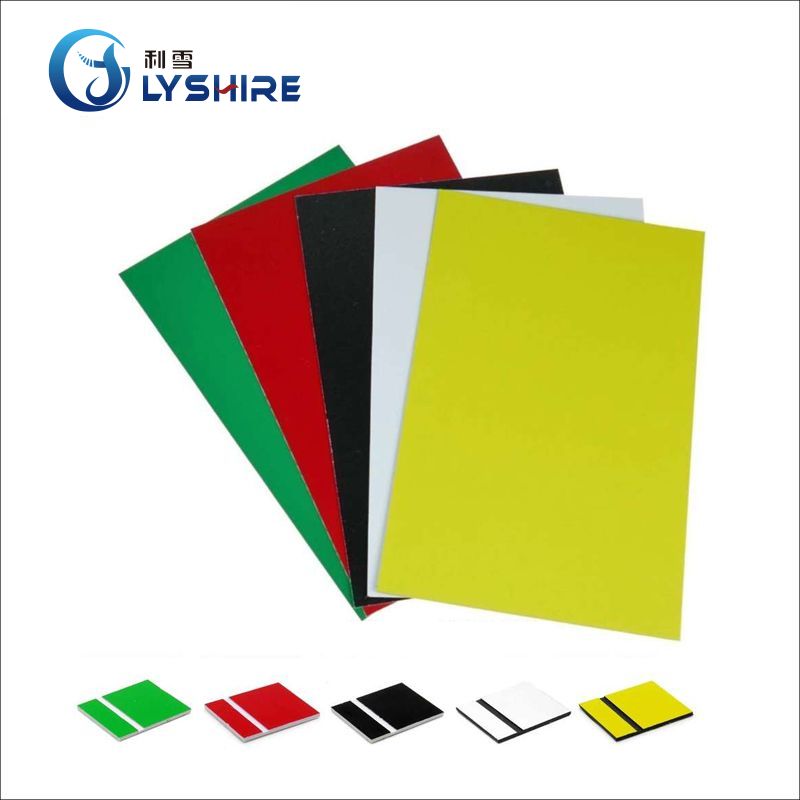

The material selection of the back glue laser is closely related to the usage scenario. Products made of PET material are tough and wear-resistant, suitable for the surface of frequently touched items, such as mobile phone cases, notebook covers, etc.; PVC material is more flexible and can adapt to curved surface pasting, which can be used for decoration such as water cups and cylindrical devices. Some products will also add wear-resistant coatings to improve the scratch resistance of the surface. Even in frequent contact in daily use, it can maintain the integrity of the texture and extend the service life.

Application extension from decoration to function

In addition to the decorative function, the functional properties of backing glue laser sheets are also gradually being explored. In the field of identification, its eye-catching laser texture can make the signboard clear and recognizable in an environment with insufficient light; in the packaging industry, it can replace the traditional gold stamping process and achieve high-end packaging effect at a lower cost; in industrial production, some special backing glue lasers can also be used as light reflective materials to improve the design Prepare for the safety. This extension from decoration to function has expanded its scope of application.

Lyshire focuses on the research and development and production of this material. The company continues to optimize the laser technology and backing performance. The products launched not only ensure the exquisiteness of the texture, but also pay attention to the convenience of installation and durability of use. Whether it is daily decoration or industrial applications, they can provide reliable material support, so that this new material can better integrate into the actual life scene.