What Makes ABS Double Color Sheet work in real projects?

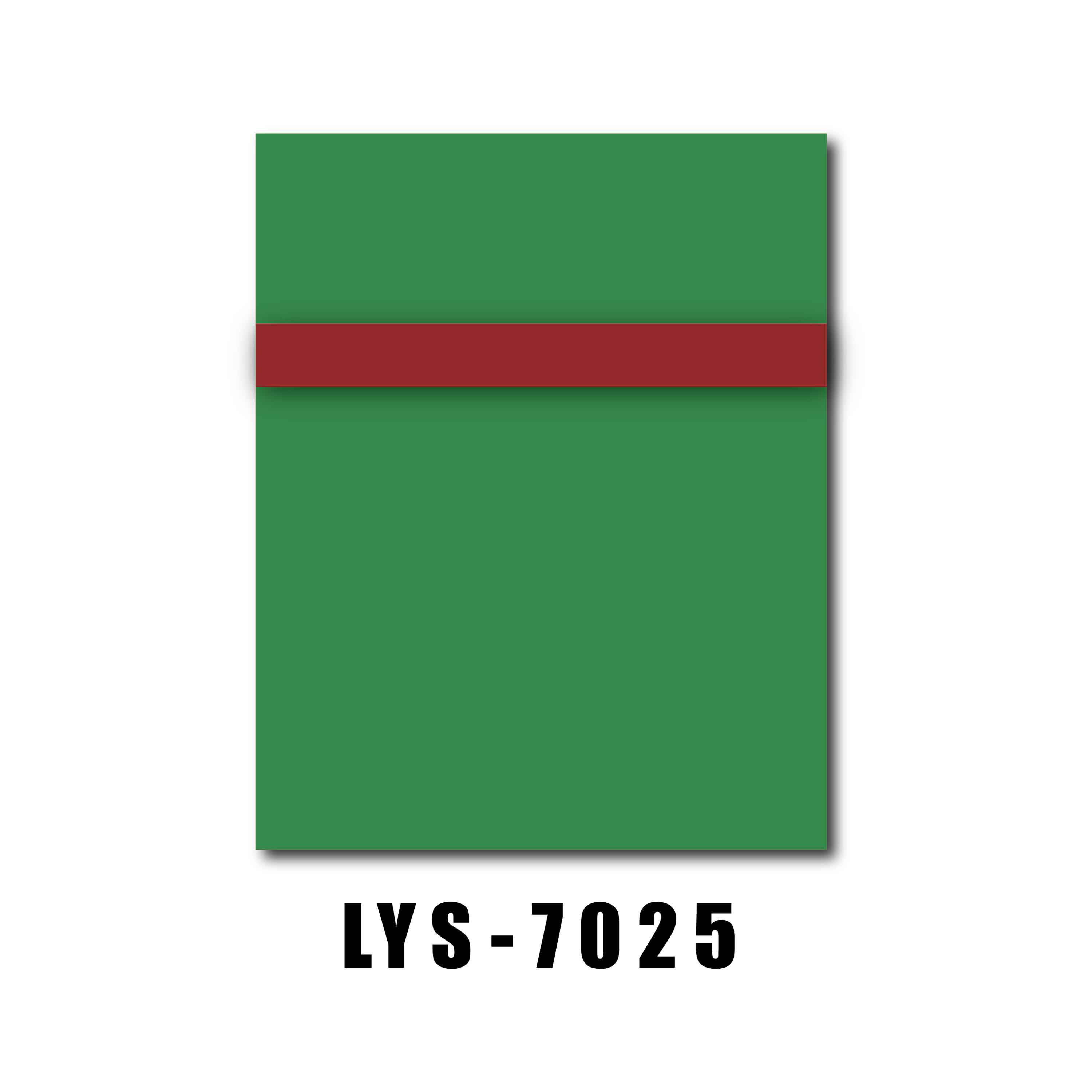

I didn’t plan to collect plastic sheets; I just needed engraved signs that stayed sharp and readable after a long shift. The material that kept bailing me out was ABS Double Color Sheet—engrave the cap and the core pops, no paint fil. A few orders in, a sample set landed on my bench with a small maker’s mark I’d seen around—LYSHIRE—and the steady color, even cap thickness, and clean edges convinced me this was the dependable route for badges, wayfinding plates, and neat interior trims.

What exactly is ABS Double Color Sheet and why does the layering help?

It is a co-extruded plastic sheet with a contrasting top layer over an ABS base. I remove the cap during engraving and the core color appears with crisp edges. The layered build means I can get high contrast without paint fills, and the ABS core keeps the sheet tough, slightly flexible, and easy to machine for flat signs or curved trims.

Where do I use it without headaches?

- Retail and office signboards that need consistent brand colors

- Backlit or edge-lit display panels when I want tidy engraved text

- Nameplates, badges, instrument panels, and control labels

- Directional and safety wayfinding that must stay legible

- Gift craft panels and interior décor in small series

How do I choose among the three common types?

In day-to-day work I group sheets into three families. One set is tuned for general rotary engraving and indoor installs. Another set carries a UV-resistant cap for outdoor signage. A third set is built for laser systems where I want fast color reveal with minimal residue. The table below is how I explain the differences to buyers who want clear choices.

| Category | Typical use | Cap layer behavior | Best engraving method | Common thickness range | UV and weather | Notes from real jobs |

|---|---|---|---|---|---|---|

| General indoor engraving sheet | Office signs, badges, control labels, interior plaques | Thin contrasting cap for sharp micro text | Rotary cutters and small-format CNC | 0.8–3.0 mm overall with 0.08–0.3 mm cap | Best indoors with normal cleaning | Fast cycle time and smooth edges with single-flute bits |

| Outdoor weatherable engraving sheet | Building markers, wayfinding, door plates, equipment tags | UV-stabilized cap that resists chalking and fade | Rotary or CNC with shallow multi-pass strategy | 1.0–4.0 mm overall with thicker cap for durability | Designed for sun and rain exposure | Holds color better on south-facing walls and gateways |

| Laser-optimized engraving sheet | Fine logos, barcodes, fast prototype plates | Cap releases cleanly under laser without gummy residue | CO₂ laser with tight focus and good exhaust | 0.6–2.5 mm overall with precise cap thickness | Indoor or short-term covered outdoor installs | Sharp contrast at low power settings for tiny fonts |

Which thickness and engraving depth make my text readable at a glance?

- For badges and small tags I like 1.2–1.6 mm overall with 0.15–0.25 mm engraving depth

- For door plates and panels I move to 2.0–3.0 mm overall with 0.25–0.35 mm depth for bold text

- For tactile arrows or pictograms I set wider stroke widths instead of pushing deeper cuts

How do I cut, engrave, and bond without warping?

- I use single-flute upcut or O-flute bits on CNC to keep chips large and cool

- I keep feed rates lively and spindle speeds moderate to avoid melting

- I run light finishing passes for clean shoulders on small letters

- I deburr with a soft brush rather than solvents so edges stay crisp

- I bond with acrylic-based tapes or structural adhesives on clean, dust-free surfaces

How do I keep color consistency across reorders?

I keep a swatch deck and record batch numbers. On recurring brand work I lock a color code and request the same batch family. The better lines I use keep tight tolerances on cap thickness and color drift, so reorders drop into place without re-profiling every toolpath.

What should I expect on lead time and logistics?

I work with a manufacturer in China that builds and exports at scale, so mixed color shipments and private labels are routine. With over twelve years of export experience, the team ships regularly to North and South America, Australia, and Europe. That reach helps with predictable packing, documents, and transit. For most color mixes I plan one to two weeks for production plus ocean or air time depending on the lane.

Which buyer pain points do I see most and how do we fix them?

- Small text chipping gets solved with sharper single-flute tooling and a lighter roughing pass

- Outdoor fade risk drops when I step up to the weatherable cap and specify matte finishes

- Laser soot or haze clears with higher air assist and a faster pass at lower power

- Adhesive failure on textured walls improves with a primer wipe and foam acrylic tapes

Can I get samples quickly and what will they prove?

I send hand-size sample plates in two or three contrasting colorways. I suggest engraving one line at your smallest intended font and one bold logo. If both read cleanly under room light, the production run will follow suit.

Do you want a supplier who can build and ship without the guesswork?

If you need guidance on which sheet type fits your signage or labeling plan, contact us and tell me the install location, size, and process you prefer. I will suggest a stack-up, send samples if needed, and quote clear lead times. For inquiries on custom colors, private labels, or regional shipping options, please contact us now and I will reply with a detailed plan.