Why is a Laser Engraving Laminate Sheet still my most reliable choice for durable signage and branding today?

When I first refreshed a batch of machine plates for a small fabrication shop, I wanted crisp contrast, fast turnaround, and labels that could survive solvents and sunlight. After trying a few plastics and paints, I landed on Lyshire because their material consistency let me dial in settings quickly. The standout performer was the Laser Engraving Laminate Sheet, which gave me clean edges, stable color reveal, and far fewer reworks than metal mark or paint-fill methods.

What exactly makes a Laser Engraving Laminate Sheet different

Unlike single-color plastics, these sheets stack a thin cap over a contrasting core. A CO₂ laser vaporizes the cap to expose the core, producing high contrast text and graphics in one pass. That structure delivers speed and repeatability without paint, ink, or post-processing.

- One-pass contrast — engrave and reveal in a single operation with no messy infill.

- Tight edge detail — fine text and QR codes remain legible at small sizes.

- Stable colors — cap and core combinations keep branding consistent across runs.

- Less cleanup — minimal residue and easy wipe-down reduce cycle time.

- Flexible formats — sheets cut cleanly for tags, control panels, badges, and wayfinding.

Which specs matter when I am planning a job

I look at cap thickness, core resin, surface finish, adhesive options, and environmental resistance. For example, a Laser Engraving Laminate Sheet with a thinner cap engraves faster; a matte finish hides fingerprints; an outdoor-rated core with UV stabilizers extends life on equipment housings.

- Cap thickness — thinner caps reveal contrast at lower power and higher speed.

- Core resin — acrylic cores suit crisp detail; modified plastics can add toughness.

- Surface finish — matte reduces glare; brushed textures elevate nameplates.

- Adhesive backing — saves assembly time for flat panels and small tags.

- Environment — heat, UV, and solvents determine indoor vs outdoor grades.

How do common use cases compare for my workflow

To keep quoting fast, I map use cases to material choices and baseline settings, then fine-tune with a small test swatch. Here is a practical matrix I use when deciding between finishes and cores for a Laser Engraving Laminate Sheet.

| Scenario | Sheet structure | Finish | Typical thickness | Baseline CO₂ pass | Outdoor exposure | Adhesive option | Notes |

|---|---|---|---|---|---|---|---|

| Indoor equipment tags | Thin cap over acrylic core | Matte | 1.2–1.6 mm | Low power, high speed single pass | Not required | Yes | Great for dense text and barcodes on flat surfaces |

| Control panels and nameplates | Medium cap over rigid core | Brushed or satin | 1.6–3.2 mm | Medium power, medium speed single pass | Limited splash | Optional | Readable at angle under shop lighting with reduced glare |

| Outdoor signs and asset plates | UV-stabilized cap over weatherable core | Textured matte | 1.6–3.2 mm | Medium power single pass or two light passes | Required | Mechanical fasten or outdoor adhesive | Best for sunlight, washdowns, and temperature swings |

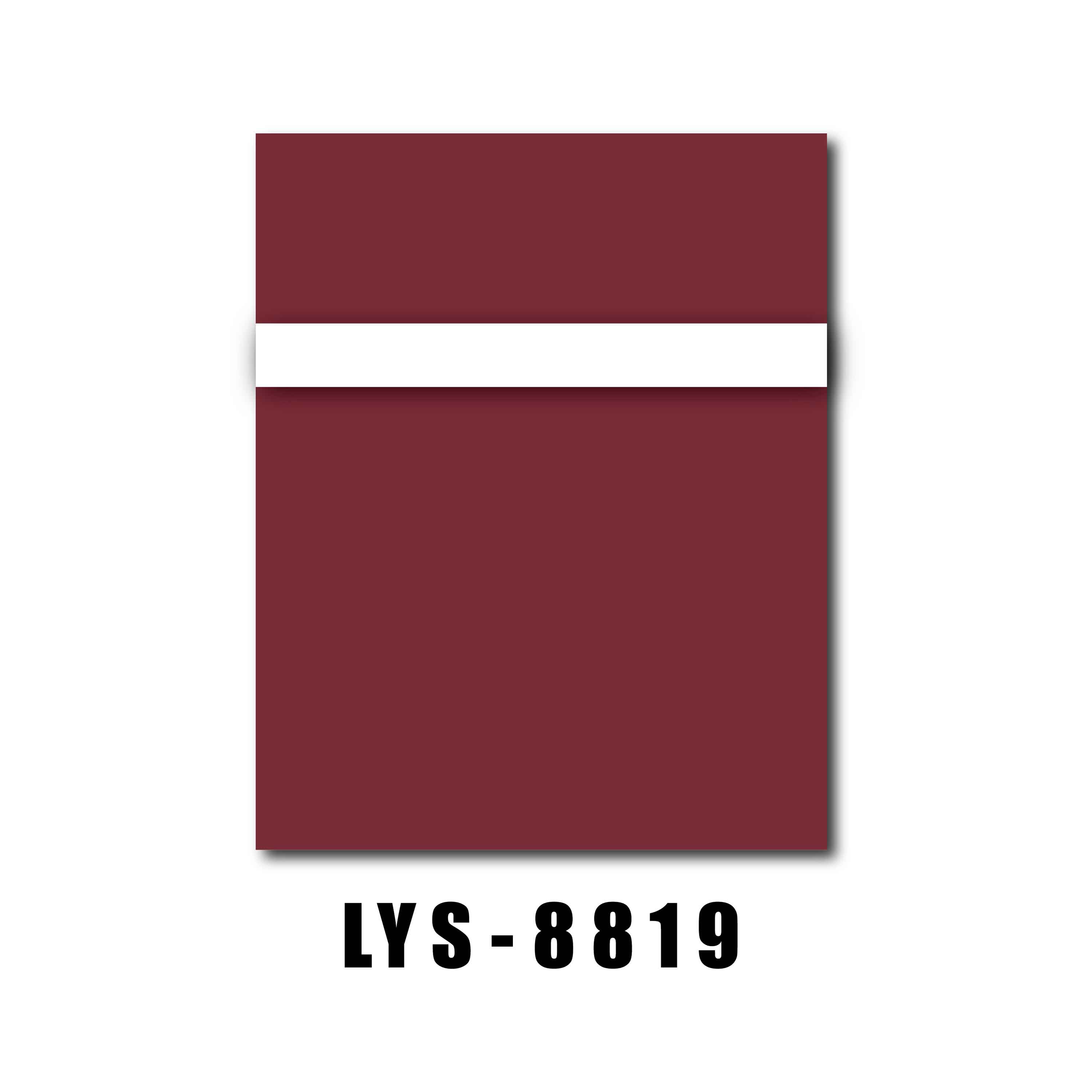

How do I pick colors that balance brand and readability

- High-contrast pairs — white on black or yellow on black read fastest on machinery.

- Brand alignment — match accent colors for faceplates while keeping text contrast strong.

- Lighting realities — matte white on dark cores remains readable in glare-prone areas.

- QR performance — dark modules on light backgrounds scan more reliably.

Can I speed up production without losing detail

- Vector first — keep artwork in true vectors for sharp glyphs and efficient toolpaths.

- Nesting — tile plates tightly and share cut lines to reduce waste.

- Focus and airflow — dial in focus height and use steady extraction to keep edges clean.

- Test swatch — a 20×20 mm gradient block quickly reveals the sweet spot for a run.

What problems does a Laser Engraving Laminate Sheet solve for my customers

- Ghosting and paint bleed — no paint fill means crisp letters with zero seep.

- Inconsistent color — the revealed core color is stable across batches.

- Slow post-processing — single-pass engraving eliminates masking and drying time.

- Small-run economics — on-demand sheet cutting beats waiting for metal etch lead times.

Where does long-term durability come from in real use

Longevity depends on the cap chemistry, UV stabilizers, and the thickness you choose. Outdoor plates last longer with textured matte caps that hide abrasion, while indoor control panels focus on readability and fingerprint resistance. If a project needs compliance documentation, I request the latest data sheet from the supplier and log it with the job so maintenance teams know what was installed.

Why do I keep a Laser Engraving Laminate Sheet in my standard quoting kit

I can move from proof to finished parts quickly because settings are repeatable and parts leave the laser ready to mount. For reorders, I simply pull the stored profile and run a verification swatch. That consistency is why a Laser Engraving Laminate Sheet remains my default for industrial labels, badges, and equipment plates.

How does Lyshire fit into my procurement plan

I lean on Lyshire when I need steady quality and dependable surface finishes across colorways. Their sheets cut cleanly, the caps engrave without unpredictable melting, and availability is strong enough for repeat contracts. If a client changes a spec, I can swap to a compatible color pair without rethinking my entire process.

What should I do next if I am scoping a new line of parts

- List the environments for each part and group them by indoor or outdoor exposure.

- Pick two candidate finishes and run a 5-minute swatch on each.

- Lock a single settings profile per thickness to simplify future reorders.

- Confirm mounting early by choosing adhesive-backed sheets or pre-drilling fixtures.

Am I ready to spec the material for my next batch

If you want the mix of speed, contrast, and durability I rely on, choose a Laser Engraving Laminate Sheet that fits your environment, then standardize settings and artwork for repeat runs. I am happy to share sample swatches and help match finishes to your application.

Would you like samples or a fast quote

Tell me the size, thickness, finish, and quantity you have in mind, and I will suggest the most efficient path from prototype to production. If you are comparing options, I can ship a small kit so you can test on your machines. For pricing, lead times, or technical guidance on a Laser Engraving Laminate Sheet, please contact us or send your drawing and I will return a clear quote with recommended settings.