Why Do I Choose Two Color Engraving Plastic For Clearer Signs And Longer Life?

2025-12-11

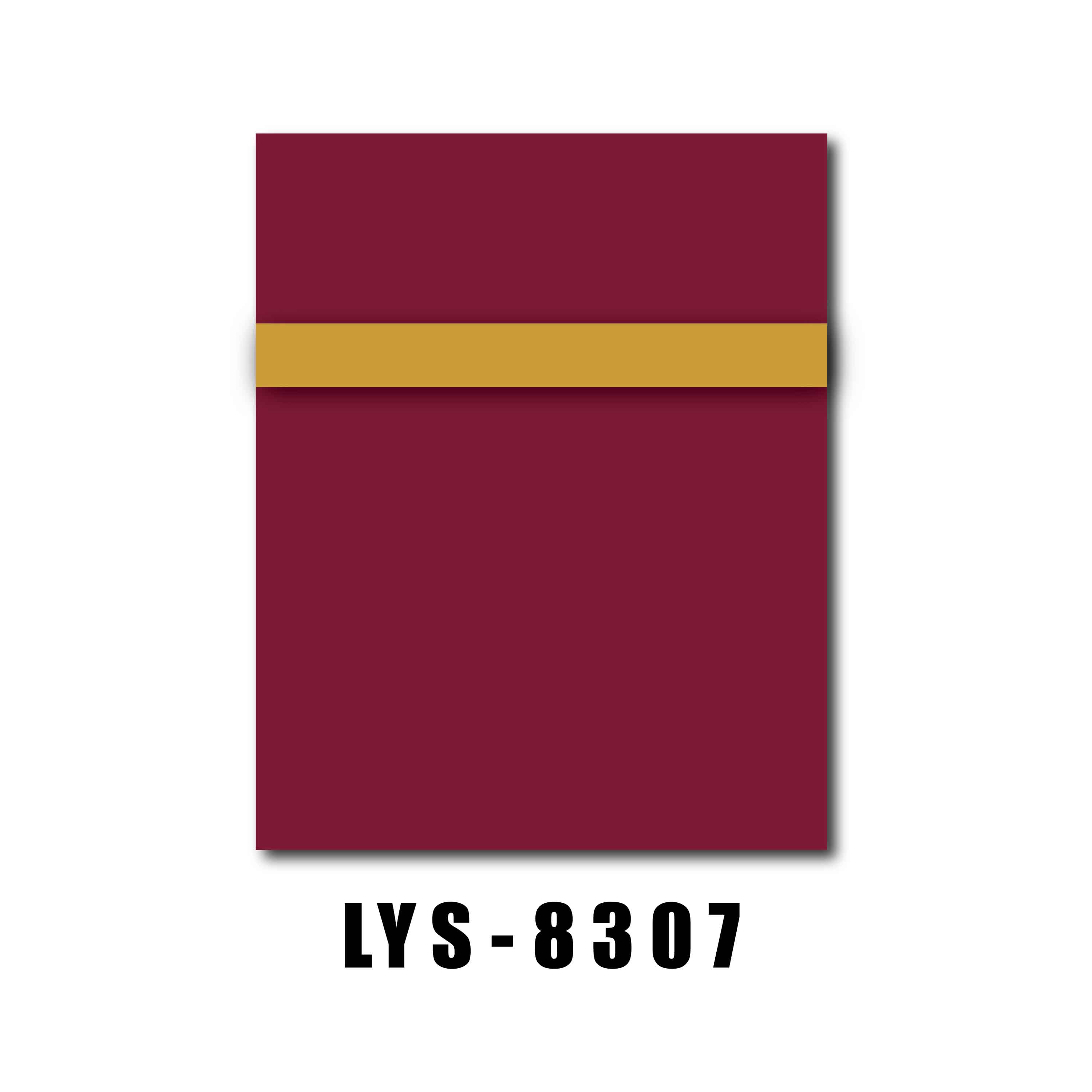

When I moved from painted tags to layered laminates, the difference in clarity and durability was immediate. Working with Lyshire, I learned how Two Color Engraving Plastic solves the smearing, fading, and touch-up headaches that used to eat my time. Instead of relying on surface inks, I engrave through a micro-thin cap to reveal a contrasting core, so the message stays readable even after rough cleaning and outdoor exposure. In this guide, I’ll share how I audit projects, choose sheet specs, and machine Two Color Engraving Plastic so the results look crisp on day one—and still look crisp a year later.

What problems does Two Color Engraving Plastic actually fix?

- Ghosted text and chipped paint that make safety labels hard to read after a few wipes.

- Inconsistent colors from batch to batch when paint or ink formulas change.

- Slow rework cycles because surface graphics scratch during installation.

- UV fading on outdoor plates where printed layers degrade quickly.

- Small fonts bleeding on curved or textured substrates.

With Two Color Engraving Plastic, the contrast is structural, not painted on. I engrave once, clean, and ship—no varnish, no infill, no drying racks.

How do I choose the right sheet structure for my job?

- Cap thickness — For fine icons or 6–8 pt text, I prefer a thin cap so a shallow pass reveals the core cleanly without widening strokes.

- Core color — I pick the core based on viewing distance: darker cores for high-glare environments, lighter cores for dim control rooms.

- Surface finish — Matte hides fingerprints on access panels; gloss pops on lobby signs; brushed masks light scratches on tools.

- Adhesive or rigid — PSA-backed sheets speed up installs on painted metal; rigid sheets screw onto enclosures without curling.

- Environment — For outdoors, I spec UV-stabilized caps and temperature-tolerant cores so the contrast in Two Color Engraving Plastic stays consistent through seasons.

Which tools and parameters give me clean edges without polishing?

- Laser — Short, fast passes prevent heat bloom; I test on scrap to lock power/speed where edges look sharp but not charred.

- Rotary — A 0.2–0.5 mm depth with a sharp carbide cutter keeps inner corners crisp; I vacuum at the bit to clear chips.

- Vector order — I engrave small text first, cut outer profiles last to avoid micro-vibration after the part loosens.

- Cleanup — I use a mild, non-solvent cleaner; the cap and core of Two Color Engraving Plastic resist common detergents, so legibility survives routine wipes.

Where does Two Color Engraving Plastic outperform metal, paint, or print?

- Machine nameplates that need fast, repeatable serialization.

- Control panels where oily hands would smear ink but not engraved contrast.

- Asset tags that must survive barcode scanning, handling, and cleaning.

- Directional and safety signage that must stay readable under UV and rain.

- Retail price rails or shelf markers that change often and must cut cleanly.

What specs should I compare before I issue a purchase order?

| Spec | Why it matters | Typical choice I make |

|---|---|---|

| Overall thickness | Stiffness and engraving headroom | 0.8–1.6 mm for tags; 1.6–3.2 mm for panels |

| Cap thickness | Minimum line weight and micro-text clarity | Thin cap for 6–8 pt fonts; thicker cap for bold graphics |

| UV stability | Outdoor colorfastness over seasons | UV-stabilized cap and core for exterior signage |

| Surface finish | Glare control and scratch masking | Matte for industrial, gloss for front-of-house, brushed for tools |

| Adhesive backing | Install speed and substrate compatibility | High-tack PSA for painted metals; no PSA for screw-mounting |

| Operating temperature | Dimensional stability near heat or cold | Wide-range plastic blend for enclosures and outdoors |

How do I plan color contrast so small text stays readable?

On glossy surfaces with ambient glare, I use mid-tone caps over deep cores to avoid washout. For dim workshops, I reverse it—light cores under darker caps. Because the contrast in Two Color Engraving Plastic is permanent, I can trust 2–3 mm text heights on tight panels without post-fills or touch-ups.

What workflow keeps prototypes fast and production consistent?

- One test card — I engrave a small matrix (fonts, line weights, QR codes) on the actual sheet and log the winning settings.

- Locked templates — I freeze kerning and stroke weights that proved legible on my test card, then reuse them across jobs.

- Batch nesting — I nest tags by thickness and finish so cutter swaps are minimal and waste drops.

- Quality checks — I swipe each tag with cleaner; if any detail disappears, I adjust depth before the batch proceeds.

Why does total cost of ownership favor Two Color Engraving Plastic?

The labor I save matters more than a few cents per sheet. No masking, no painting, no ink curing—just engrave, cut, clean, and pack. Fail-rates drop because contrast is built in. On repeat orders, my setup time is minutes. That is where Two Color Engraving Plastic pays for itself.

How do I align my brand, safety needs, and compliance without design drift?

I keep a color book of cap/core combinations that match my brand’s palette and safety standards. With Two Color Engraving Plastic, the approved combos stay consistent across plants and vendors, so lockout tags, valve markers, and lobby plaques look related—even when different teams produce them.

What do I watch for when switching suppliers?

- Color consistency across batches measured against a simple swatch card.

- Cap thickness tolerance so micro-text depth remains predictable.

- Flatness of sheets to avoid lensing or out-of-focus engraving.

- Protective films that peel cleanly and don’t leave residue.

- Clear data sheets with recommended laser/rotary windows for Two Color Engraving Plastic.

Where do I start if I want reliable results on my first run?

I begin with a small kit of common color pairs, one matte and one gloss, and I document my winning settings on a sample card that ships with the client’s first order. That transparency reduces support tickets and speeds reorders. Once teams see how readable and durable Two Color Engraving Plastic can be, they usually standardize on it for tags, panels, and safety signage.

Would you like help picking a stack that fits your environment?

If you’re weighing finishes, cap/core colors, or engraving parameters, tell me about your lighting, cleaning chemicals, and text sizes. I’ll recommend a short list and share a test-card template you can run in under ten minutes. When you’re ready, contact us to compare options, request samples, or place a trial order—use the form on the site and include “Two Color Engraving Plastic” in your note so we route it quickly. For quotes, project audits, or custom color matching, contact us and we’ll get you set up.